Maintenance | DBtek

Understanding Splice Loss: Causes and Fixes

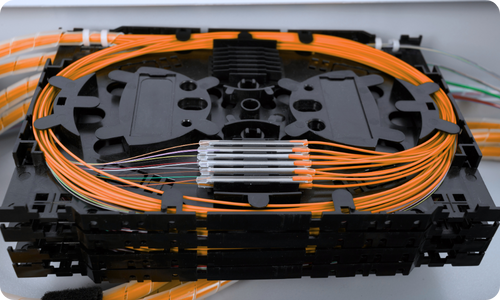

Splice loss is the reduction of signal power at the splice point. While some loss is unavoidable, excessive loss can compromise network performance. Understanding its causes and solutions is critical for reliable fiber optic installations.

Common Causes of Splice Loss

- Poor Fiber Cleave: Angled or chipped cleaves prevent proper core alignment.

- Dirty Fibers: Dust, oil, and residue reduce splice quality.

- Misalignment: Incorrect positioning of fibers leads to light leakage.

- Core vs Cladding Mismatch: Using different fiber types without adjustment causes increased loss.

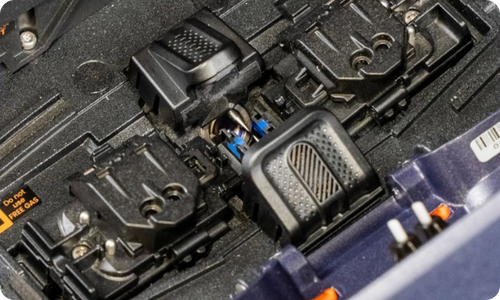

- Worn Electrodes: Old or contaminated electrodes create unstable arcs.

- Environmental Factors: Wind, dust, or vibration during splicing can disrupt alignment.

Fixes and Best Practices

- Always use a precision cleaver and replace blades when worn.

- Clean fibers thoroughly with alcohol before cleaving.

- Regularly calibrate your fusion splicer for arc stability.

- Replace electrodes after ~3,000 splices.

- Use protective tents or covers in outdoor environments.

- Verify fiber type compatibility before splicing.

Measuring Splice Loss

- Estimated Loss: DBtek splicers provide immediate on-screen loss estimates.

- Verification with OTDR: For critical projects, confirm loss using an Optical Time Domain Reflectometer.

Excessive splice loss is avoidable with proper preparation, equipment maintenance, and attention to environmental factors. DBtek’s GT40 and GT60 splicers, combined with proper technician practices, ensure consistently low splice loss and long-term network performance.